Timing Belt XH

Timing Belt XH Specification

- Belt Type

- Timing Belt XH

- Features

- High torque transmission capacity

- Surface Finish

- Textured

- Material

- Rubber

- Type

- Belt

- Structure

- Flexible

- Resistant Feature

- Heat Oil and Wear Resistant

- Usage & Applications

- Industrial machinery and equipment

About Timing Belt XH

It may solve the problems such as low transmission efficiency and lubrication oil required under the status of high speed when using the chain, distance limit between the drive part and slave drive part when using the gear.

Glass fiber as tensile member , no elongation of rubber belt.

Excellent heat -resistance , oil-proof and wearing resistance.

Higher transmission efficiency can be guaranteed under the condition of large change of operation speed and temperature.

Its performance can be expected stably and safely during the process of high speed rotation.

Exceptional Torque and Flexibility

The Timing Belt XH delivers superior torque transmission, ensuring that industrial machines function efficiently even under heavy loads. Its flexible structure allows seamless movement and easy adaptation to various mechanical setups, reducing maintenance interruptions.

Engineered for Longevity

With its advanced rubber material and textured surface finish, the belt stands up against harsh conditions-notably heat, oil, and abrasion. This durability extends the lifecycle of the belt, minimizing downtime and replacement costs for industrial operations.

Versatile Industrial Applications

Specifically designed for use in machinery and equipment, the Timing Belt XH serves diverse sectors across India. Its resilient construction and reliable performance make it suitable for any industry where dependable timing and power delivery are crucial.

FAQ's of Timing Belt XH:

Q: How does the Timing Belt XH provide high torque transmission capacity?

A: The Timing Belt XH features a strong rubber construction and a textured surface, enabling it to grip pulleys effectively. This ensures efficient torque transfer between machine components, reducing slippage and enhancing power transmission in demanding industrial settings.Q: What benefits does the heat, oil, and wear resistance offer to industrial users?

A: Its resistance to heat, oil, and wear means the Timing Belt XH maintains its performance in tough environments. This translates to a longer operational lifespan, fewer breakdowns, and decreased maintenance costs, offering significant reliability for continuous industrial use.Q: When should the Timing Belt XH be replaced in industrial equipment?

A: Replacement times vary depending on usage intensity and environment, but regular inspections are recommended. If noticeable signs of wear, cracks, or reduced tension appear, it is advisable to replace the belt promptly to prevent equipment downtime.Q: Where can the Timing Belt XH be applied within industrial sectors?

A: This timing belt is suitable for a wide array of industrial machinery and equipment, including conveyor systems, packaging machines, and automated assembly lines, making it an essential component in many manufacturing and processing plants.Q: What is the process for installing the Timing Belt XH?

A: Installation involves aligning the belt properly on the pulleys, ensuring tension is within recommended limits, and checking for smooth movement after fitting. It's important to consult the machinery manual or a professional technician for optimal installation.Q: How does the flexible structure of the belt benefit industrial machines?

A: The belt's flexibility allows it to conform easily to different pulley arrangements and absorb minor misalignments, reducing stress on machinery components and contributing to smoother, quieter operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Timing Belts Category

"ARITECH" Timing Belt

Belt Type : Synchronous Gear Belt

Type : Other, Timing Belt

Material : Rubber

Features : Low noise, long service life, minimal stretch

Usage & Applications : Automotive, Packaging, Industrial Automation

Surface Finish : Uniform; precisionmolded teeth

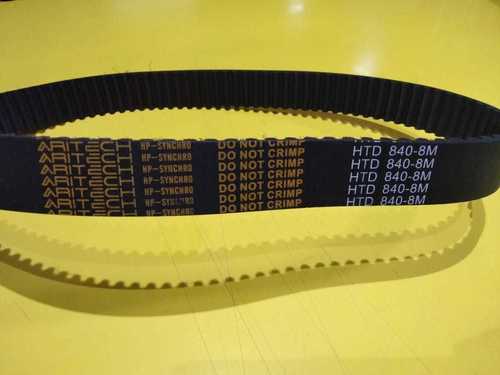

Timing Belt 8m

Belt Type : Timing Belt

Type : Other, HTD 8408M

Material : Rubber with reinforced fiberglass

Features : Precision and durable

Usage & Applications : Automotive industrial machinery and robotics

Surface Finish : Smooth and toothed

Multi Ribbed Belt PJ

Belt Type : PJ Poly Ribbed Belt

Type : Other, Multi Ribbed Belt

Material : Rubber Compound

Features : Multi Ribbed Design Enhanced Durability

Usage & Applications : Industrial Machinery Automotive Applications

Surface Finish : Textured Surface

Timing Belt 3m

Belt Type : Timing Belt

Type : 3M HTD Timing Belt, Other

Material : Rubber

Features : Durable Efficient Precisionoriented

Usage & Applications : Mechanical systems Automotive Industrial Machinery

Surface Finish : Textured

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free