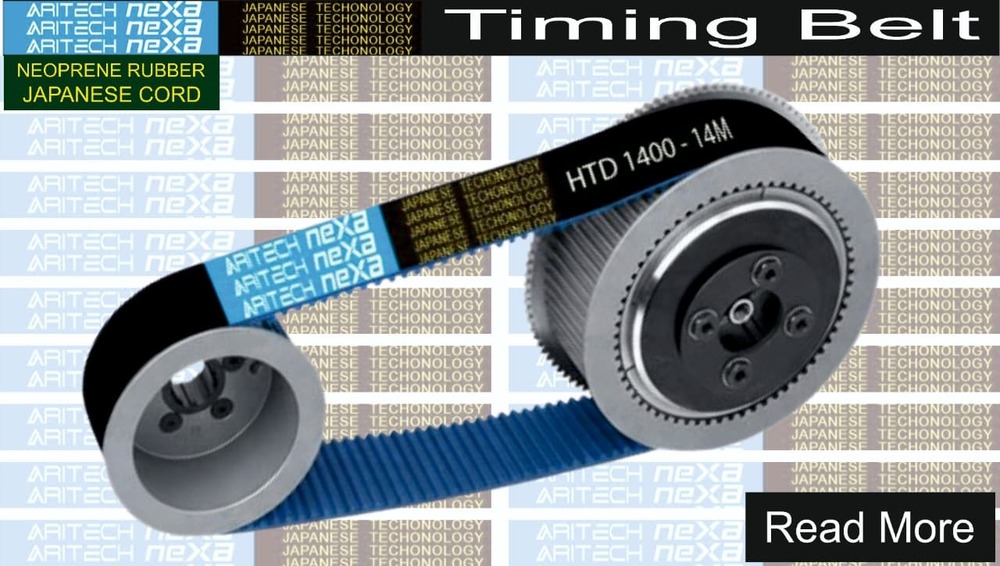

"ARITECH" Timing Belt

Price 100.0 INR/ Piece

"ARITECH" Timing Belt Specification

- Power Source

- Mechanical

- Belt Type

- Synchronous Gear Belt

- Surface Finish

- Uniform; precision-molded teeth

- Thickness

- Standard (varies per model) Inch

- Features

- Low noise, long service life, minimal stretch

- Material

- Rubber

- Type

- Timing Belt

- Structure

- Belt

- Belt Conveyor

- Compatible

- Vertical Conveyor

- Supported

- Pneumatic Conveyor

- Supported

- Resistant Feature

- Oil, Heat, and Abrasion Resistant

- Load Capacity

- High; suitable for industrial machinery Metric Ton

- Voltage

- Not Applicable (mechanical component) Biot ( Bi)

- Speed

- Optimized for synchronous transmission mm/m

- Warranty

- Yes

- Usage & Applications

- Automotive, Packaging, Industrial Automation

- Color

- Black

- Temperature Tolerance

- -20C to +80C

- Installation

- Easy to install and replace

- Length

- Custom and standard lengths

- Tooth Profile

- Curved, anti-slip design

- Width Range

- Available in multiple standard widths

"ARITECH" Timing Belt Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Asia, South America

- Main Domestic Market

- All India, West India, Central India, Bihar, Uttar Pradesh, Jammu and Kashmir, South India, Chandigarh, East India, Goa, Uttarakhand, Karnataka, Assam, North India, Mizoram, Chhattisgarh, Haryana, Manipur, Andaman and Nicobar Islands, , Gujarat, Maharashtra, West Bengal, Kerala, Daman and Diu, Rajasthan, Sikkim, Andhra Pradesh, Lakshadweep, Odisha, Meghalaya, Delhi, Himachal Pradesh, Madhya Pradesh, Nagaland, Telangana, Tripura, Arunachal Pradesh, Jharkhand, Dadra and Nagar Haveli, Tamil Nadu, Punjab, Pondicherry

About "ARITECH" Timing Belt

Material: Black Rubber- It may solve the problems such as low transmission efficiency and lubrication oil required under the status of high speed when using the chain, distance limit between the drive part and slave drive part when using the gear.

- Glass fiber as tensile member , no elongation of rubber belt.

- Excellent heat -resistance , oil-proof and wearing resistance

- Higher transmission efficiency can be guaranteed under the condition of large change of operation speed and temperature.

- XL-L-H-3M-5M-8M-14M-T5-T10-D8M-D5M-DH-DL-XH-XXHSERIES

- We have Also full Range ARITECH Brand FLAT BELTS special quality

- I assume your industry uses various types of belts in significant quantity in machinery, hence would like to discuss further about your existing requirement and specifications.

- Do let me know your contact details and I shall get in touch with you at the soonest.

Precision Synchronous Gear Belt

ARITECH Timing Belts feature precision-molded teeth with a curved profile, offering uniform engagement and optimized speed for synchronous transmission. Their robust construction ensures low noise and long service life, suitable for high-capacity industrial machinery and automation systems.

Resilient Design for Tough Environments

Built to resist oil, heat, and abrasion, ARITECH timing belts retain their integrity in extreme operating conditions. The temperature tolerance of -20C to +80C allows for dependable performance across a wide range of industries, including automotive and packaging.

Flexible Sizing and Easy Installation

Available in multiple standard widths and customizable lengths, ARITECH belts accommodate varied mechanical setups. The easy-to-install structure minimizes downtime, making replacement and maintenance straightforward for factories and assembly lines.

FAQs of "ARITECH" Timing Belt:

Q: How does the curved tooth profile benefit ARITECH Timing Belt performance?

A: The curved tooth profile ensures optimal meshing with gears, reducing slippage and noise while maintaining precise synchronous transmission, which improves overall efficiency and reliability in demanding automation and machinery applications.Q: What applications are best suited for ARITECH Timing Belts?

A: These timing belts are ideal for industrial machinery, vertical and pneumatic conveyors, packaging systems, and automotive setups, thanks to their high load capacity and resistance to oil, heat, and abrasion.Q: When should I consider replacing my ARITECH Timing Belt?

A: Replacement is recommended when signs of significant wear, stretch, or loss of synchronous transmission efficiency are observed. Regular inspection schedules help ensure maximum service life and machinery safety.Q: Where can I purchase ARITECH Timing Belts in India?

A: ARITECH Timing Belts are available through authorized distributors and suppliers across India, providing both custom and standard specifications to meet various industrial requirements.Q: What is the process for installing an ARITECH Timing Belt?

A: Installation is straightforward due to the belts precision design. Simply align the belt with the pulley system, ensure correct tension, and secure it as per the machinerys guidelines, facilitating easy replacement and minimal downtime.Q: How does the anti-slip and resistance features add value to ARITECH Timing Belts?

A: The anti-slip design and resistance to oil, heat, and abrasion extend the belts operational life, reducing maintenance frequency and ensuring consistent, reliable performance in harsh environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Timing Belts Category

Fenner Timing Belt

Price 1000 INR / Piece

Minimum Order Quantity : 1000 Pieces

Material : Rubber with reinforced fibers

Type : Other, Timing Belt

Features : High durability and precise synchronization

Resistant Feature : Other

Timing Belt

Price 1000 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Rubber/Polyurethane

Type : Other, H Type Timing Belt

Features : High precision durable

Resistant Feature : Other, Heat resistant wearresistant

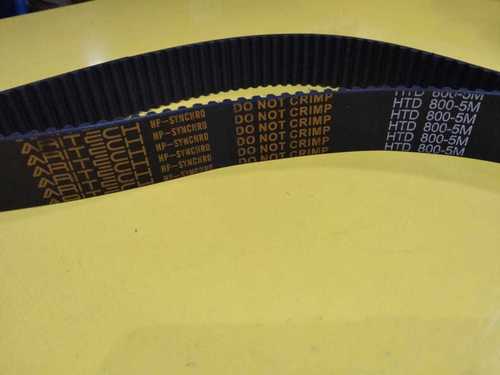

Timing Belt 5m

Material : Rubber with Reinforcement

Type : HTD Timing Belt, Other

Features : High Efficiency Resistant to Crimp

Resistant Feature : Other, Crimp Resistance

Rubber Timing Belt ( Double Side) Dl

Minimum Order Quantity : 1 , , Unit

Material : Rubber

Type : Belt Conveyor

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS