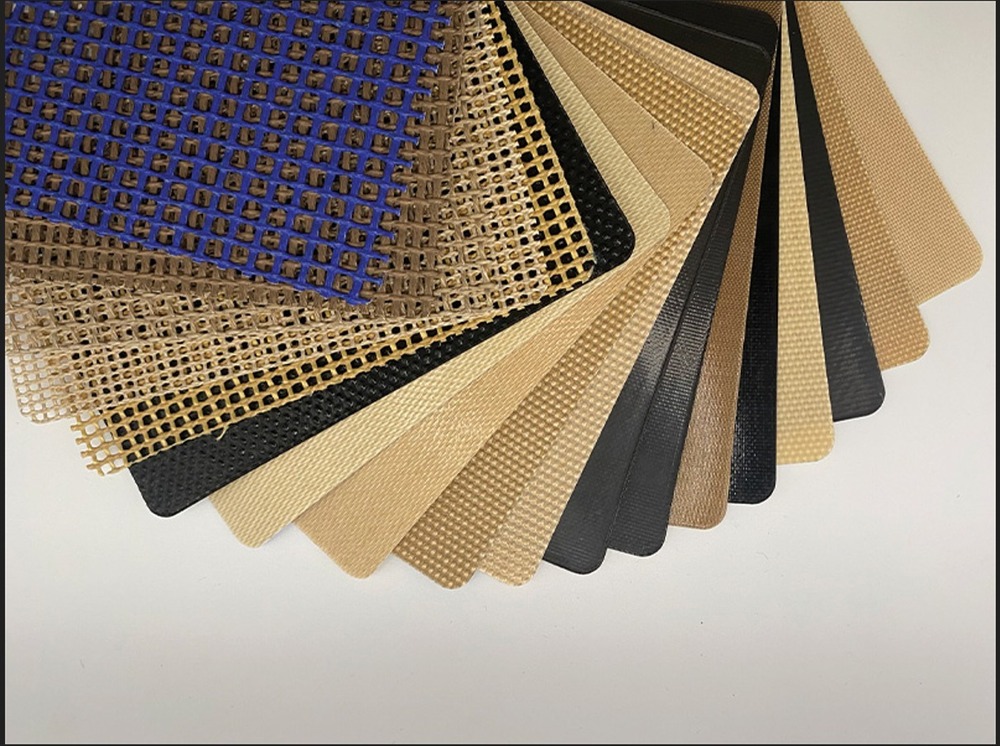

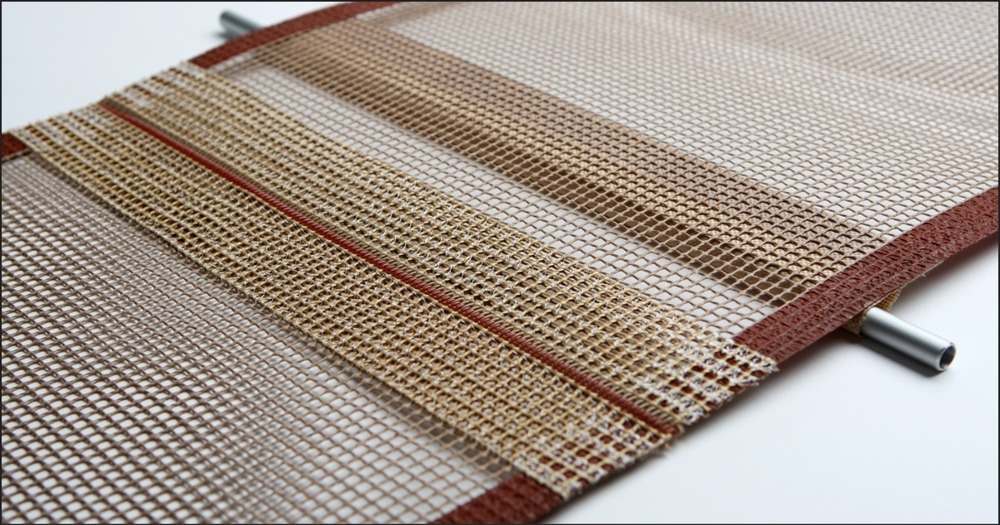

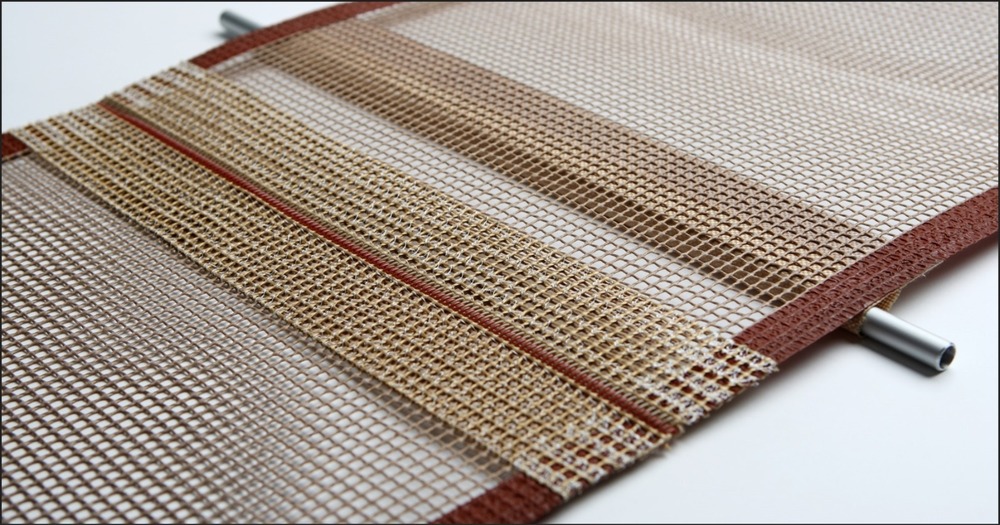

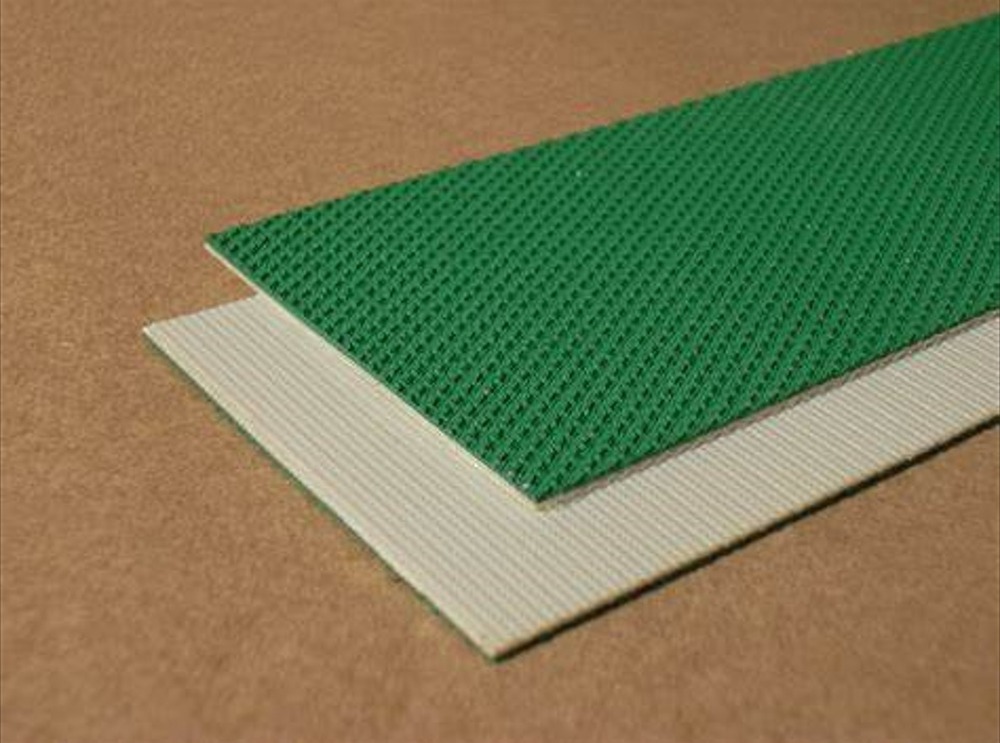

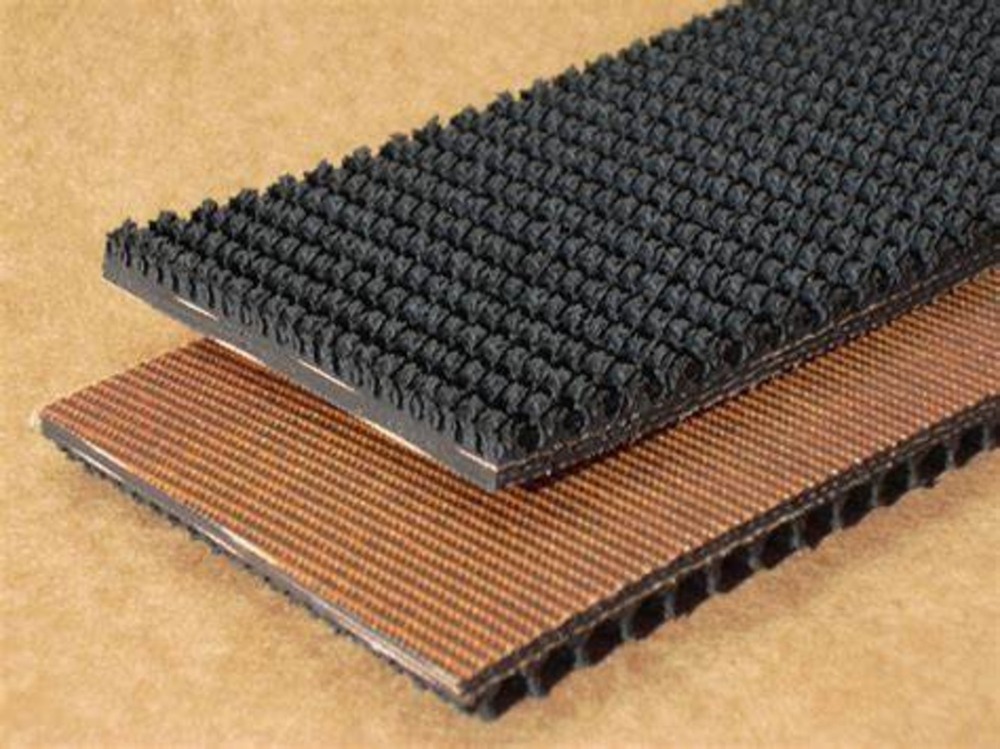

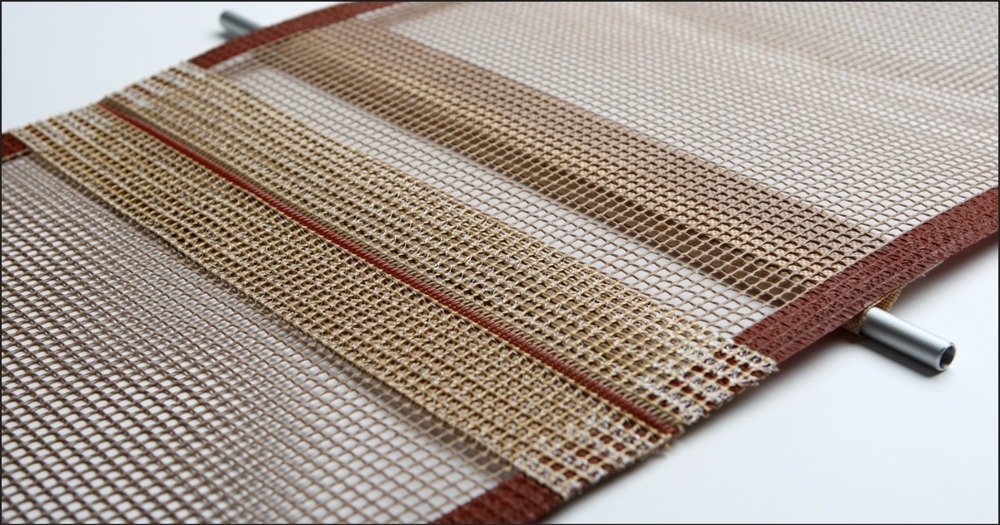

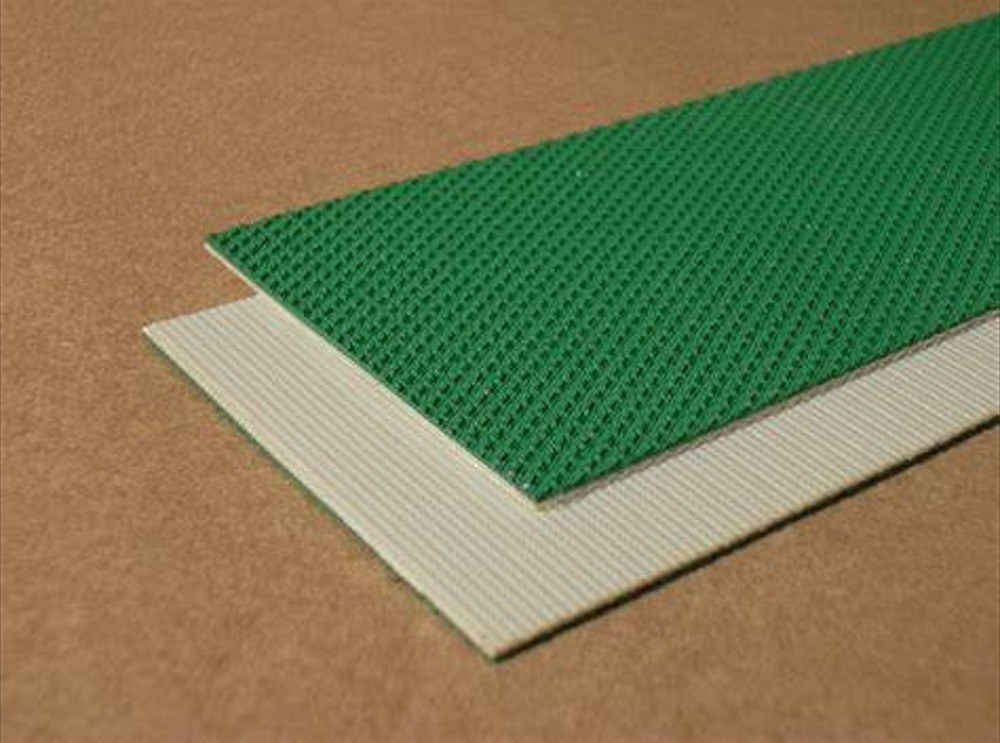

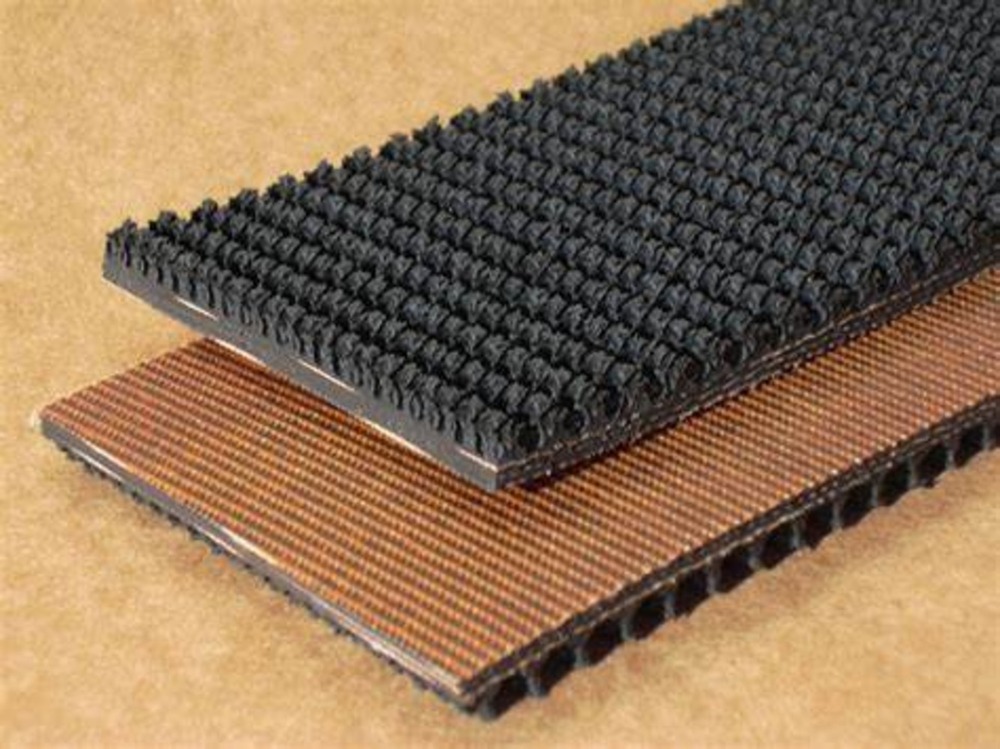

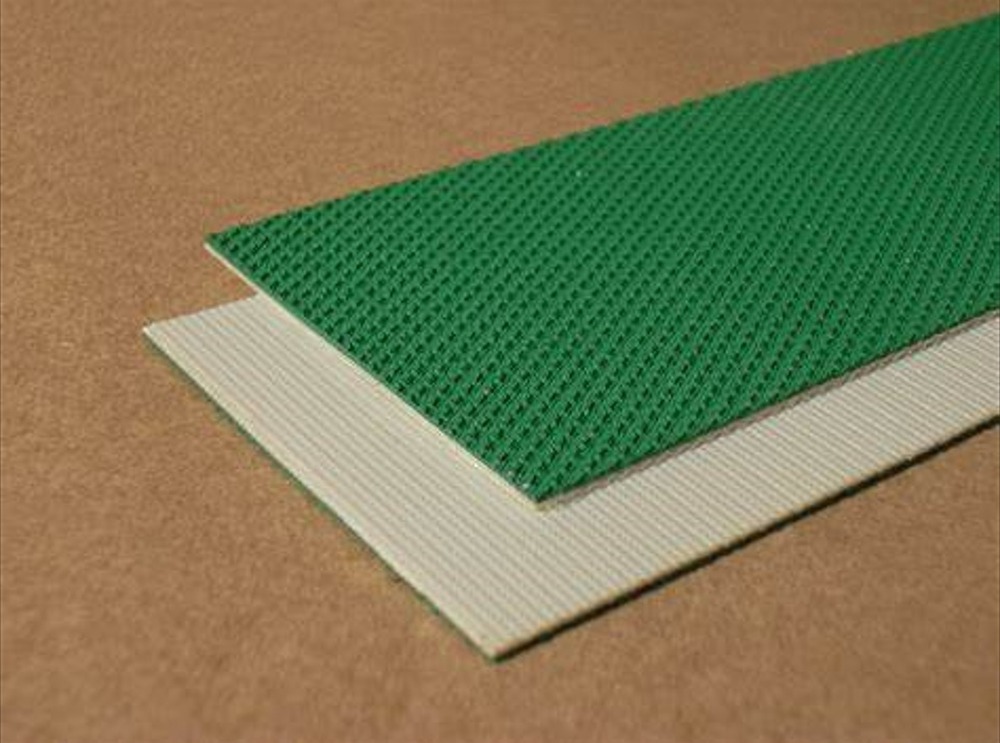

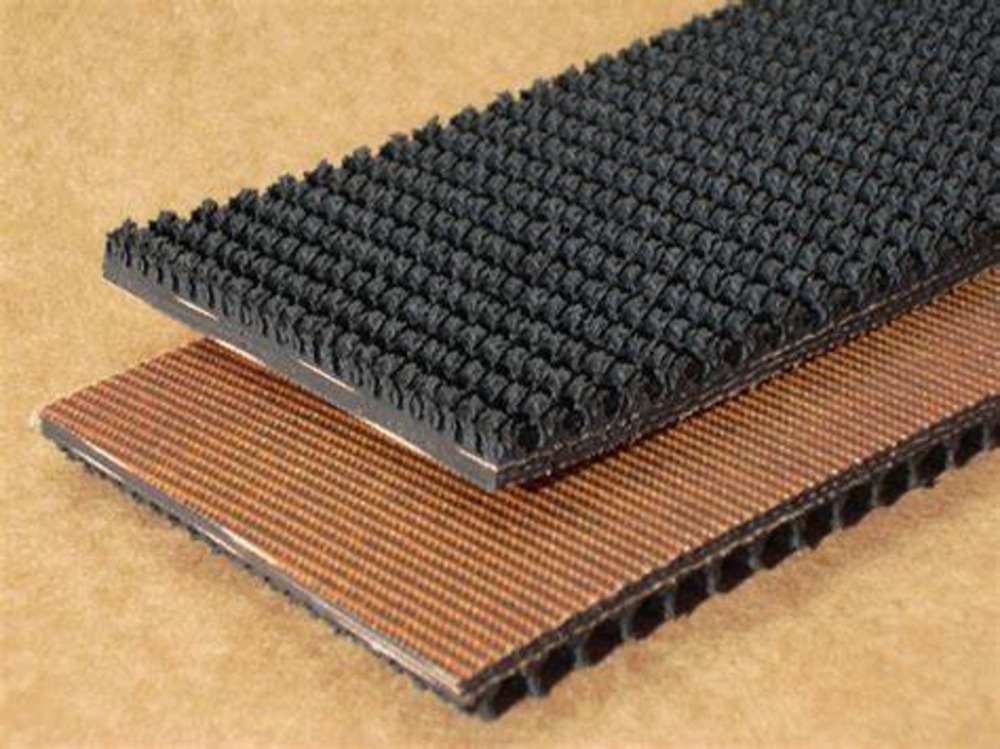

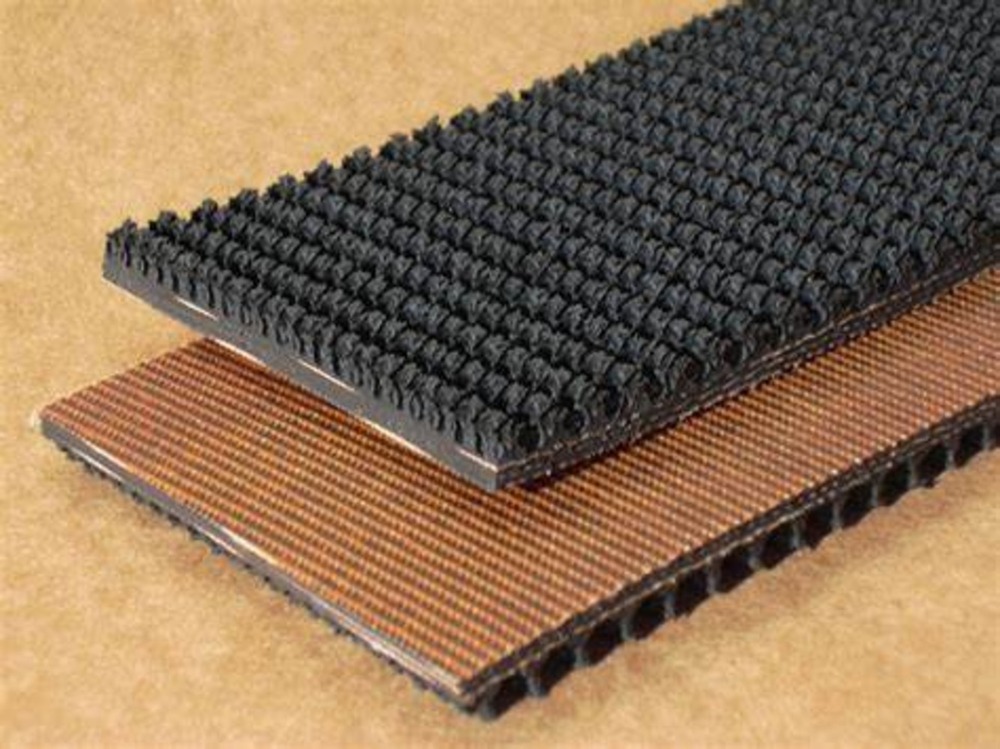

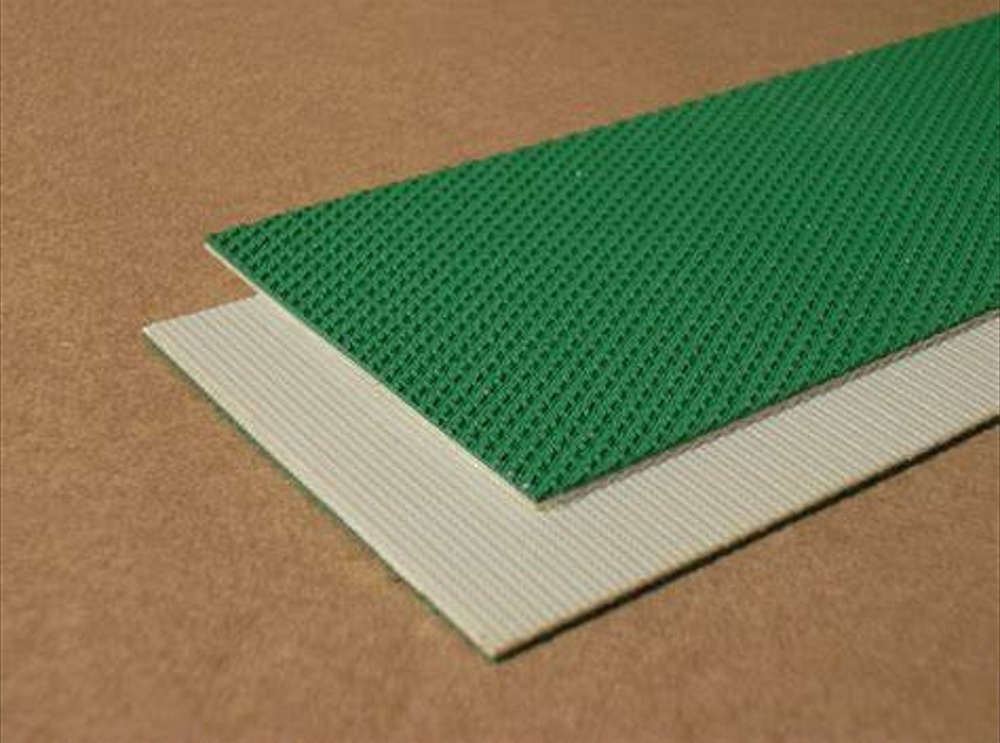

PTFE-coated fabric belts

Price 8000.00 INR/ Piece

PTFE-coated fabric belts Specification

- Usage

- FOOD TEXTILE PRINTING

- Size

- 29.5

- Product Type

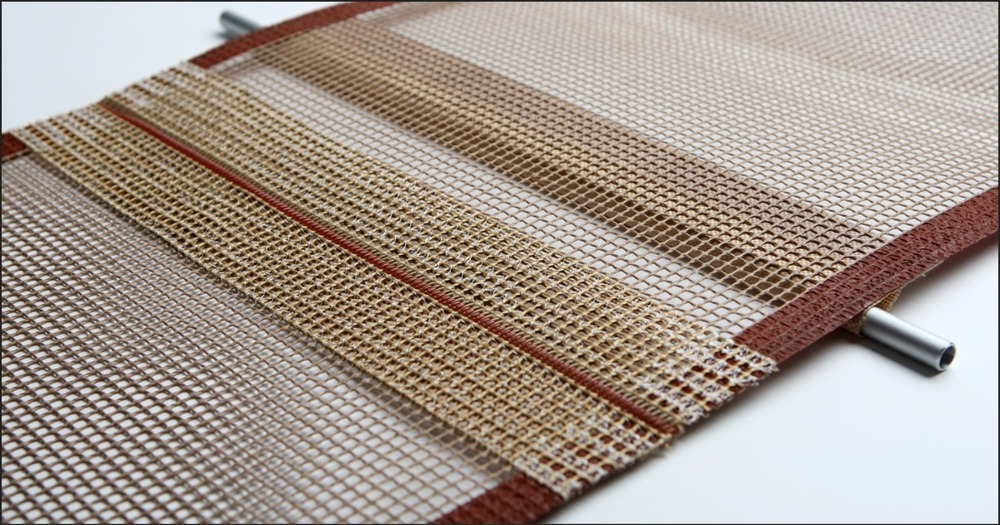

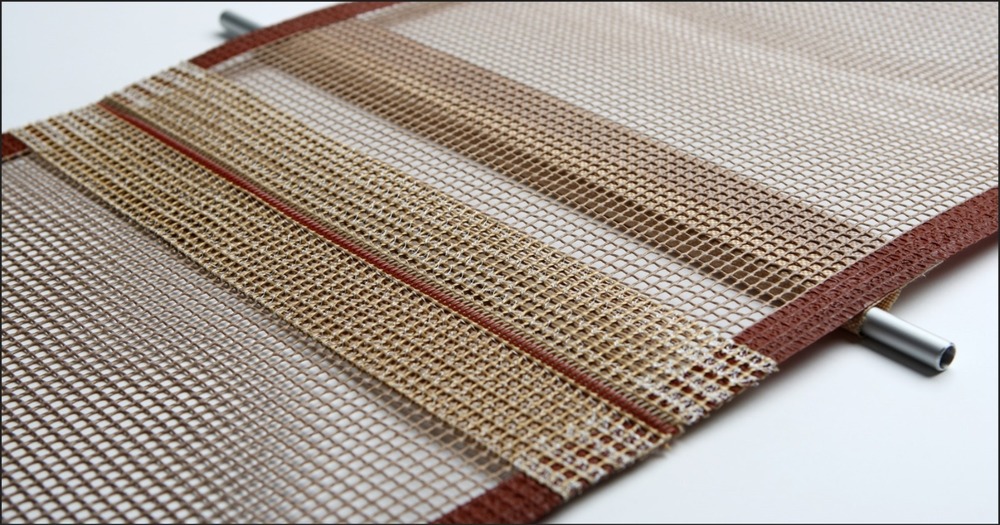

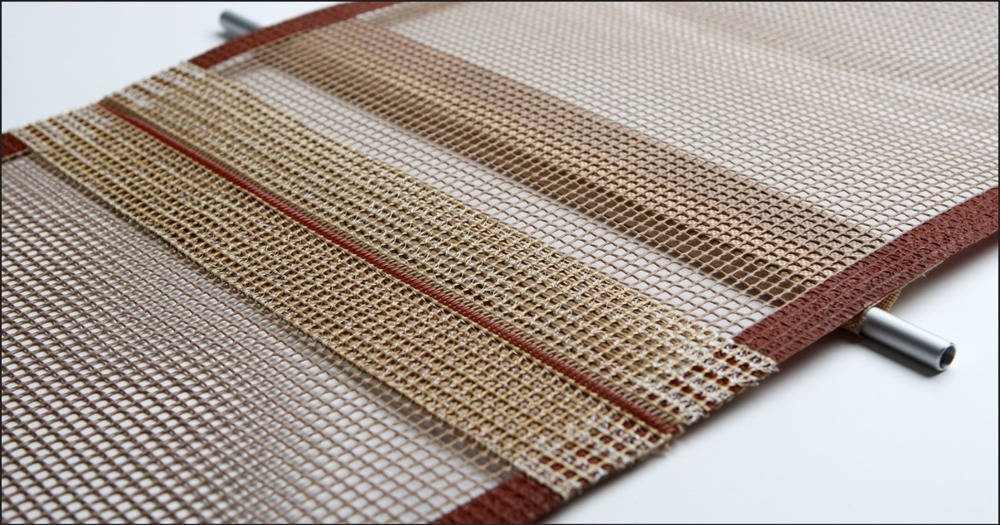

- MESH CONVYOR

- Weight

- 1KG TO 25KG GSM (gm/2)

- Color

- BROW BLCK

- Length

- 115 Meter (m)

PTFE-coated fabric belts Trade Information

- Minimum Order Quantity

- 20 Pieces

- FOB Port

- SURAT

- Payment Terms

- Paypal, Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 6 Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Central America, North America, South America, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About PTFE-coated fabric belts

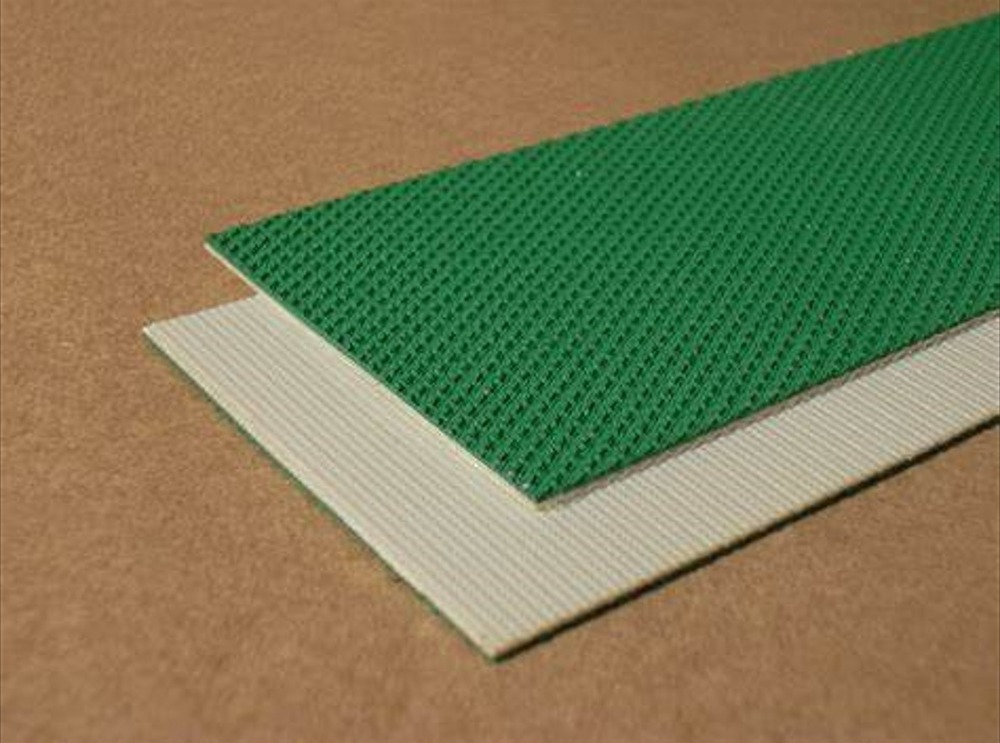

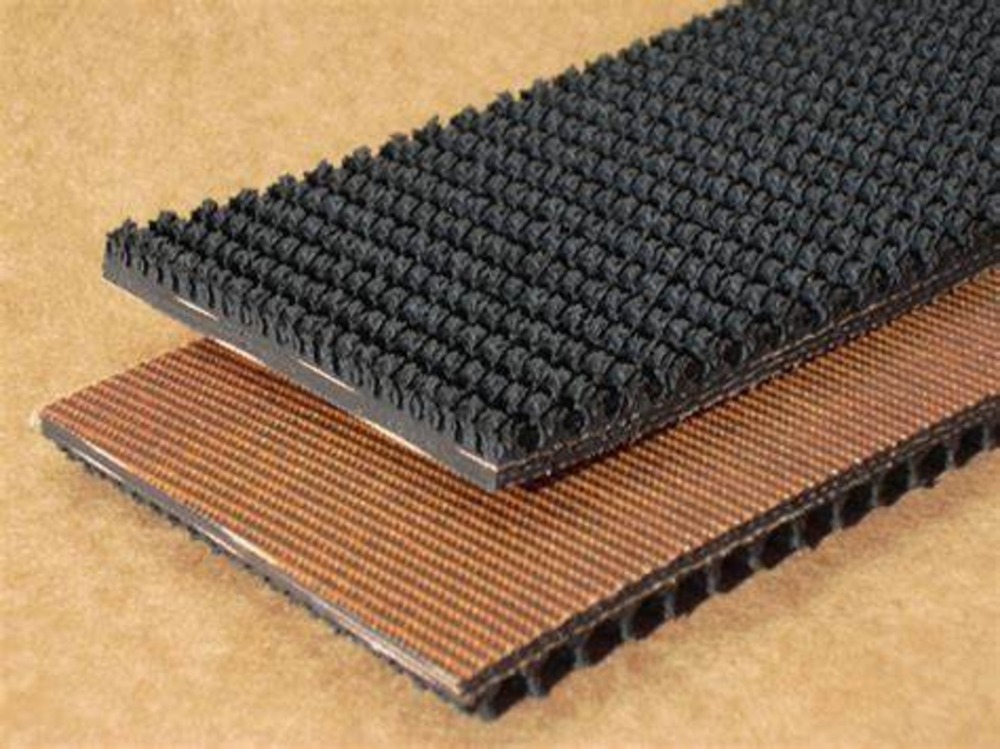

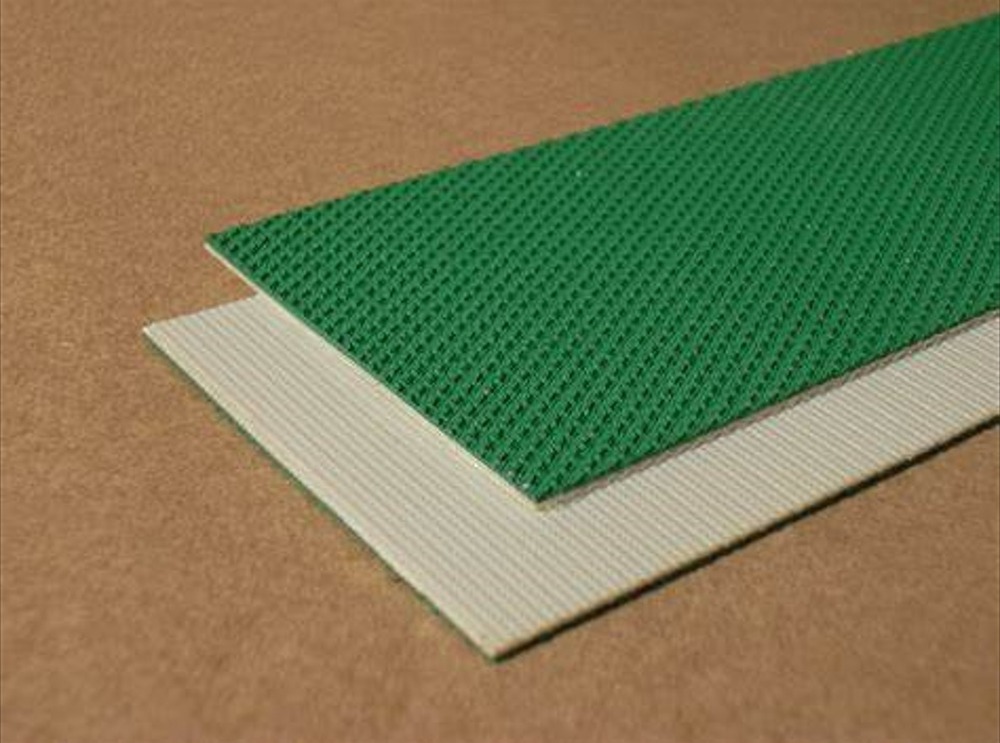

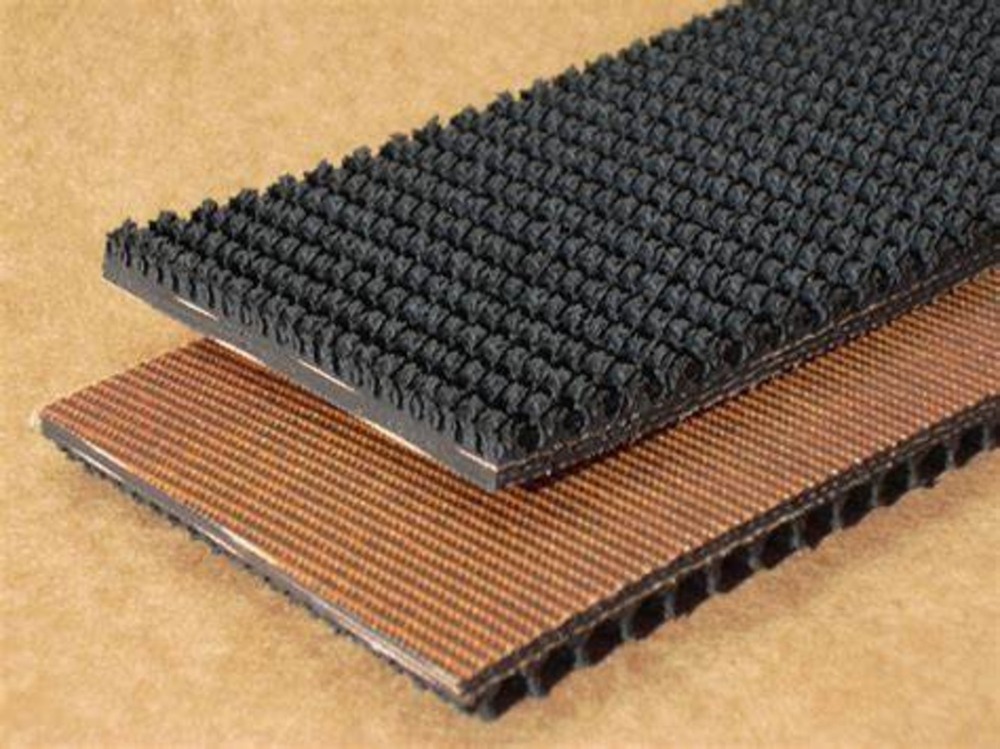

PTFE belt refers to a conveyor or timing belt made from polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its non-stick properties, high temperature resistance, and chemical inertness. PTFE belts are commonly used in industrial applications, particularly in environments where heat resistance, low friction, and durability are essential.

Here are some of the key characteristics and uses of PTFE belts:

Key Characteristics:

-

Heat Resistance: PTFE can withstand extremely high temperatures, typically up to 260C (500F), and even higher in some cases. This makes PTFE belts ideal for high-temperature processing, such as in ovens or dryers.

-

Non-Stick Surface: PTFE is known for its non-stick properties, which make it an excellent choice for applications where materials might otherwise adhere to the surface. This is especially useful in food processing, packaging, or any application requiring easy material release.

-

Chemical Resistance: PTFE belts are highly resistant to a wide range of chemicals and solvents, which makes them suitable for industries like pharmaceuticals, chemicals, and food processing where exposure to harsh substances is common.

-

Durability: PTFE belts are durable and resistant to wear, making them long-lasting in demanding industrial environments.

-

Low Friction: The smooth surface of PTFE reduces friction, which is advantageous for conveying goods with less resistance.

Applications:

-

Food Processing: PTFE belts are commonly used in ovens, drying tunnels, and other food production environments where temperature control and easy cleaning are essential.

-

Conveying Systems: Used in industries such as packaging, textile, and electronics for material handling where a high degree of precision and low friction is needed.

-

Printing and Coating: In industries that require precision, PTFE belts are used for curing, drying, and other processes that involve heat and materials sensitive to sticking.

-

Packaging: PTFE belts are used for sealing and packaging applications, particularly in machines that work with hot or sticky materials.

Superior Non-stick Performance

The PTFE coating on these fabric belts guarantees minimal adhesion, reducing maintenance and product loss. This feature is particularly advantageous for food production and textile printing, where cleanliness is paramount and efficiency is critical for continuous processing lines.

Versatile Industrial Applications

Designed for use in food, textile, and printing sectors, these belts accommodate a wide range of operations. Their customizable weight and robust build ensure suitable integration in both light and heavy-duty systems, making them a preferred choice among Indian manufacturers and suppliers.

FAQ's of PTFE-coated fabric belts:

Q: How are PTFE-coated fabric belts installed and maintained in industrial settings?

A: PTFE-coated fabric belts are usually installed by aligning them with machine rollers and securing them via mechanical fasteners or adhesives as per equipment requirements. Regular cleaning with non-abrasive agents is advised to maintain their non-stick properties and prolong lifespan.Q: What are the main benefits of using PTFE-coated fabric belts in food and textile printing applications?

A: These belts offer superior non-stick properties, resistance to high temperatures, and chemical inertness, which are critical in food safety and preventing ink transfer or fabric sticking in printing processes.Q: When should PTFE-coated fabric belts be replaced in production lines?

A: Belts should be replaced upon visible signs of wear, reduced non-stick performance, or when structural damage compromises efficiency. Routine inspections are recommended for early detection in high-usage environments.Q: Where are these PTFE-coated fabric belts commonly used in India?

A: These belts are widely utilized in food processing facilities, textile manufacturing units, and industrial printing plants across India due to their reliability and compliance with hygiene standards.Q: What steps are involved in the manufacturing process of PTFE-coated belts?

A: The process begins with selecting high-quality fabric, which is then evenly coated with PTFE to create a durable, heat-resistant surface. Final cuts are made according to required dimensions, followed by rigorous quality inspections.Q: How does the choice of weight (GSM) affect belt performance?

A: Selecting the appropriate GSM influences the belt's durability, flexibility, and load-carrying capacity. Higher GSM belts are suited for heavier applications, while lighter GSM variants are optimal for delicate or lighter operations.Q: What advantages do these belts provide distributors and suppliers in India?

A: Distributors and suppliers benefit from stocking PTFE-coated belts due to their high demand, versatility across industries, and reputation for reducing downtime, which enhances customer satisfaction and business potential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS