Timing Belt L

Timing Belt L Specification

- Belt Type

- Synchronous Belt

- Surface Finish

- Smooth outer surface with grooves

- Power Source

- None (Mechanically driven)

- Features

- High-performance; Precise motion transfer

- Material

- Rubber composite

- Type

- L-Timing Belt

- Structure

- Grooved design for enhanced grip

- Belt Conveyor

- Timing Belt L

- Resistant Feature

- Heat-resistant; Wear-resistant

- Voltage

- None (Passive component)

- Usage & Applications

- Industrial machinery; Automation systems

About Timing Belt L

It may solve the problems such as low transmission efficiency and lubrication oil required under the status of high speed when using the chain, distance limit between the drive part and slave drive part when using the gear.

- Glass fiber as tensile member , no elongation of rubber belt.

- Excellent heat -resistance , oil-proof and wearing resistance.

- Higher transmission efficiency can be guaranteed under the condition of large change of operation speed and temperature.

- Its performance can be expected stably and safely during the process of high speed rotation

Superior Precision and Reliability

Our Timing Belt L ensures accurate power transmission in automation systems and industrial equipment. Designed for consistent performance, its grooved profile enhances grip and synchronizes machinery components efficiently. This belt excels in applications where timing and precision are critical, offering longevity and reduced risks of mechanical slippage during operation.

Durable and Heat-Resistant Composition

Constructed from quality rubber composite, the L-Timing Belt is heat- and wear-resistant, making it ideal for prolonged use in harsh industrial environments. Its robust build minimizes the risks of wear and thermal degradation, ensuring steady performance over a wide range of operating conditions. The smooth surface finish also facilitates easy installation and maintenance.

FAQ's of Timing Belt L:

Q: How should the Timing Belt L be installed in industrial machinery?

A: The Timing Belt L should be installed by aligning its grooved side with the corresponding pulleys in your industrial machinery, ensuring tension is appropriately adjusted for smooth and accurate motion transfer. Always follow the manufacturer's guidelines for best results.Q: What materials are used in the Timing Belt L, and how do they benefit industrial applications?

A: This belt is made from a robust rubber composite, giving it excellent wear and heat resistance. These properties make it highly suitable for industrial and automation setups that require minimal downtime and reliable, long-term operation.Q: When is it recommended to replace the Timing Belt L in automation systems?

A: Replace the Timing Belt L during regular maintenance if you observe visible cracking, loss of tension, or any wear on the grooves, as timely replacement helps prevent machinery failures and ensures consistent performance in automation systems.Q: Where can I source the Timing Belt L in India?

A: You can purchase the Timing Belt L from reputable distributors and suppliers across India, including authorized dealers specializing in industrial machinery and automation components.Q: What is the process for maintaining the Timing Belt L to extend its operational life?

A: Simple periodic inspection for signs of wear or heat damage, proper tensioning, and keeping the belt clean from dust and debris will help extend its operational life and maintain high performance.Q: How does the grooved structure of the Timing Belt L improve its performance?

A: The grooved design ensures enhanced grip and precise synchronization between pulleys, reducing the chances of slippage and boosting efficiency in conveying and motion transfer applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Timing Belts Category

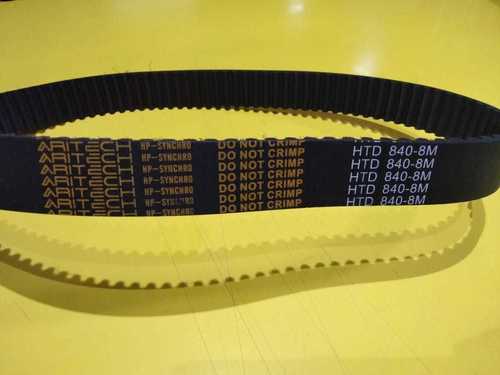

"ARITECH" Timing Belt

Price 100.0 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Belt

Belt Type : Synchronous Gear Belt

Material : Rubber

Type : Other, Timing Belt

Gt 4 timing belt

Price 500 INR / Piece

Minimum Order Quantity : 1000 Pieces

Structure : Other, Flexible and Sturdy

Belt Type : Timing Belt

Material : Rubber

Type : Other

Timing Belt 3m

Structure : Closed Loop, Other

Belt Type : Timing Belt

Material : Rubber

Type : 3M HTD Timing Belt, Other

Timing Belt 8m

Structure : Other, Toothed belt structure

Belt Type : Timing Belt

Material : Rubber with reinforced fiberglass

Type : Other, HTD 8408M

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free