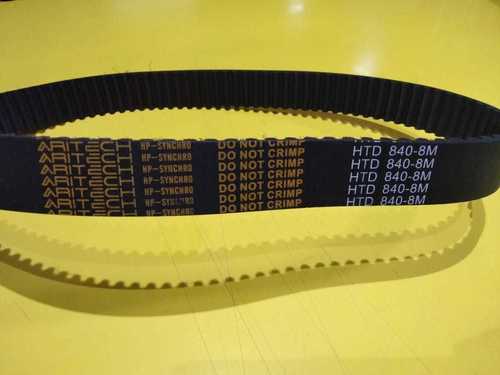

Rubber Timing Belt ( Double Side) Dl

Rubber Timing Belt ( Double Side) Dl Specification

- Usage

- Industrial

- Material

- Rubber

- Size

- Standard

- Type

- Belt Conveyor

- Structure

- Belt

- Product Type

- Industrial Timing Belt(

- Color

- Black

- Warranty

- Yes

Rubber Timing Belt ( Double Side) Dl Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 500 Units Per Month

- Delivery Time

- 7 Days

About Rubber Timing Belt ( Double Side) Dl

- Model No. : L Profile (Double Side Teeth)

- 9.525 mm teeth pitch

- It may solve the problems such as low transmission efficiency and lubrication oil required under the status of high speed when using the chain, distance limit between the drive part and slave drive part when using the gear.

- Glass fiber as tensile member , no elongation of rubber belt.

- Excellent heat -resistance , oil-proof and wearing resistance.

- Higher transmission efficiency can be guaranteed under the condition of large change of operation speed and temperature.

- Its performance can be expected stably and safely during the process of high speed rotation.

- Top Rubber : CR HNBR : Protect the lining tensile member.

- Tensile Member : Glass Fiber : Core material to pass the dynamic force.

- Teeth Rubber : CR HNBR : Protect the tensile member and maintain the shape of the rubber.

- Teeth Fabric : Elastic Fabric : Maintain the shape of the adhesive tape and teeth.

High-Quality Double Sided Timing Belts

Our double sided rubber timing belts feature a belt-on-belt structure, ideal for industrial conveyor applications. The standard size fits a variety of machinery, providing versatility and genuine compatibility with Indian manufacturing environments. Benefiting from robust rubber material, these belts ensure long-lasting performance even during continuous operation.

Dependable Performance and Support

Every belt comes with a manufacturer warranty, underscoring our commitment to quality and support. Indian distributors and suppliers ensure easy access to genuine spare parts and technical assistance, making maintenance and replacement a hassle-free process for industrial clients.

FAQ's of Rubber Timing Belt ( Double Side) Dl:

Q: How are double sided rubber timing belts typically used in industrial settings?

A: Double sided rubber timing belts are commonly utilized in belt conveyor systems within various industries. They transmit mechanical power from both sides, allowing for synchronized movement of multiple pulleys and enhancing productivity in automated processes.Q: What are the main benefits of using a double sided timing belt made of rubber?

A: Rubber double sided timing belts offer flexibility, reduced noise, great grip, and long durability. Their ability to engage with pulleys on both surfaces maximizes efficiency, minimizes slippage, and extends the operational life of the conveyor system.Q: When should a standard size double sided rubber timing belt be replaced?

A: Timing belts should be inspected regularly for signs of wear, cracks, or stretching. Replacement is recommended if any of these signs appear or according to your equipment manufacturer's maintenance schedule, especially if the belt is used continuously in demanding industrial environments.Q: Where can I purchase high-quality double sided rubber timing belts in India?

A: You can obtain our double sided rubber timing belts through authorized distributors and suppliers across India, ensuring reliable access to genuine products and warranty support.Q: What is the process for installing a double sided belt conveyor timing belt?

A: The installation involves shutting down the conveyor system, removing the old belt, ensuring pulley alignment, and carefully fitting the new double sided belt as per the manufacturer's guidelines. Proper tensioning and testing for smooth operation are crucial post-installation.Q: How does the structure of a double sided belt enhance industrial conveyor performance?

A: The double sided structure allows simultaneous engagement with pulleys on both sides, enabling more complex mechanical designs and synchronized movement, which increases the range and flexibility of industrial automation systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Timing Belts Category

Timing Belt 3m

Type : 3M HTD Timing Belt, Other

Material : Rubber

Surface Finish : Textured

Features : Durable Efficient Precisionoriented

Resistant Feature : Other, Heatresistant Wearresistant

Usage & Applications : Mechanical systems Automotive Industrial Machinery

Timing Belt 8m

Type : Other, HTD 8408M

Material : Rubber with reinforced fiberglass

Surface Finish : Smooth and toothed

Features : Precision and durable

Resistant Feature : Other, Heat and wear resistance

Usage & Applications : Automotive industrial machinery and robotics

Multi Ribbed Belt PJ

Type : Other, Multi Ribbed Belt

Material : Rubber Compound

Surface Finish : Textured Surface

Features : Multi Ribbed Design Enhanced Durability

Resistant Feature : Heat Resistant

Usage & Applications : Industrial Machinery Automotive Applications

Timing Belt L

Type : Other, LTiming Belt

Material : Rubber composite

Surface Finish : Smooth outer surface with grooves

Features : Highperformance; Precise motion transfer

Resistant Feature : Heatresistant; Wearresistant, Other

Usage & Applications : Industrial machinery; Automation systems

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS