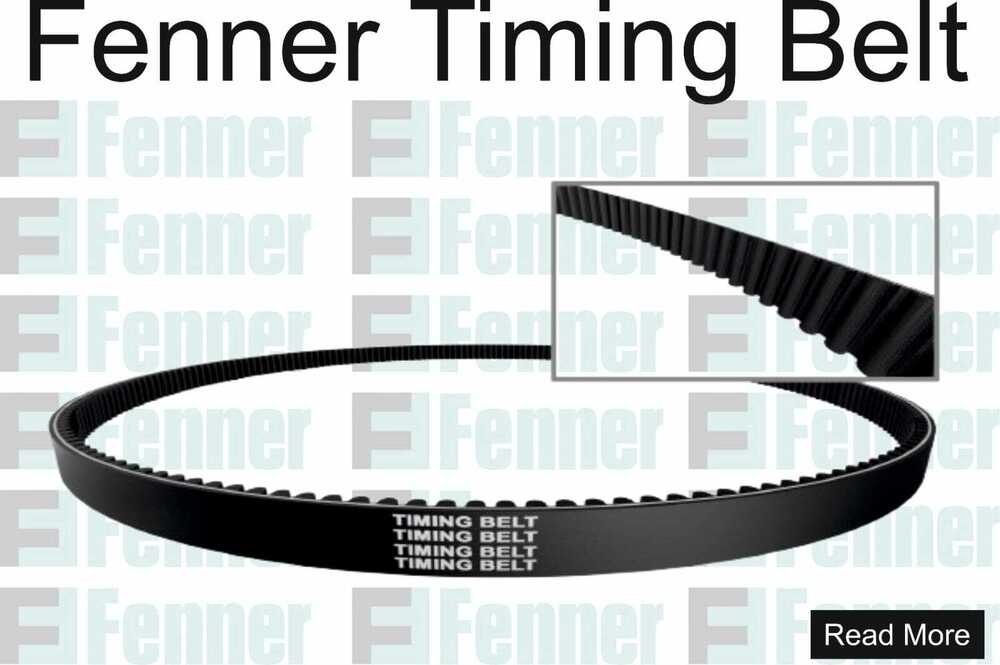

Fenner Timing Belt

Price 1000 INR/ Piece

Fenner Timing Belt Specification

- Power Source

- None

- Belt Type

- Timing Belt D5m

- Thickness

- Standard thickness for D5m configuration Micrometers (um)

- Surface Finish

- Textured for improved grip and functionality

- Features

- High durability and precise synchronization

- Material

- Rubber with reinforced fibers

- Type

- Timing Belt

- Structure

- Can be routed around pulleys for mechanical power transmission

- Belt Conveyor

- None

- Roller Conveyor

- None

- Vertical Conveyor

- None

- Pneumatic Conveyor

- Other

- Resistant Feature

- Other

- Load Capacity

- Varies based on application Tonne

- Voltage

- None Ampere (amp)

- Power

- None Microampere (A)

- Speed

- Consistent for synchronized motion m/m

- Warranty

- Varies by manufacturer

- Usage & Applications

- Industrial machinery automotive timing systems

Fenner Timing Belt Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Asia, South America, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Fenner Timing Belt

It may solve the problems such as low transmission efficiency and lubrication oil required under the status of high speed when using the chain, distance limit between the drive part and slave drive part when using the gear.

- Glass fiber as tensile member , no elongation of rubber belt.

- Excellent heat -resistance , oil-proof and wearing resistance.

- Higher transmission efficiency can be guaranteed under the condition of large change of operation speed and temperature.

- Its performance can be expected stably and safely during the process of high speed rotation.

Superior Synchronization and Durability

Fenner Timing Belt D5m delivers exceptional synchronization, essential for precision-driven applications in industrial machinery and automotive timing systems. Reinforced fiber construction ensures long-term durability, reducing maintenance needs and downtime. The robust rubber material and specialized surface grip further enhance its reliability during continuous, high-load operations.

Versatile Industrial Application

Designed to be routed around pulleys, this timing belt supports a broad range of mechanical power transmission needs. Its adaptability makes it suitable for use in various sectors, from production lines to engine timing systems. The material's resistance to wear and the standard D5m thickness make it a versatile solution for environments requiring consistent motion and load handling.

FAQ's of Fenner Timing Belt:

Q: How does the Fenner Timing Belt D5m ensure precise synchronization in machinery?

A: The Fenner Timing Belt D5m is designed with accurate tooth profiles and reinforced fibers, allowing it to transmit motion with minimal slippage. This ensures components remain synchronized, which is critical for applications such as automotive timing systems and industrial production.Q: What are the main benefits of using a reinforced rubber timing belt in industrial applications?

A: Reinforced rubber belts like the Fenner D5m offer superior durability and reduced stretch, leading to longer service life and fewer maintenance intervals. The textured surface also enhances grip, which prevents slippage and increases operational efficiency.Q: When should a Fenner Timing Belt D5m be replaced?

A: Replacement intervals depend on the application's load and usage frequency. Operators should perform regular visual inspections for signs of wear, cracks, or loss of tension, and follow manufacturer guidelines for maintenance to prevent unexpected breakdowns.Q: Where can I purchase authentic Fenner Timing Belts in India?

A: Authentic Fenner Timing Belts can be sourced through authorized distributors and suppliers across India. It is recommended to verify supplier credentials to ensure the products are genuine and covered under warranty.Q: What is the process for installing the Fenner Timing Belt D5m?

A: Installation involves routing the belt around the appropriate pulleys according to the system's specifications. Proper tensioning is crucial for optimal performance. Refer to equipment manuals or seek assistance from qualified technicians for installation guidance.Q: Can the Fenner Timing Belt D5m handle variable loads and speeds?

A: Yes, the Fenner D5m belt is designed to manage variable load capacities depending on the application. Its structural integrity and consistent speed transmission make it suitable for both heavy-duty and precision operations where synchronized motion is required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Timing Belts Category

Gt 4 timing belt

Minimum Order Quantity : 1000 Pieces

Material : Rubber

Structure : Other, Flexible and Sturdy

Type : Other

Resistant Feature : Other, Wear and Heat Resistant

Usage & Applications : Automotive Machinery

Multi Ribbed Belt PJ

Material : Rubber Compound

Structure : Other, Flexible Ribbed

Type : Other, Multi Ribbed Belt

Resistant Feature : Heat Resistant

Usage & Applications : Industrial Machinery Automotive Applications

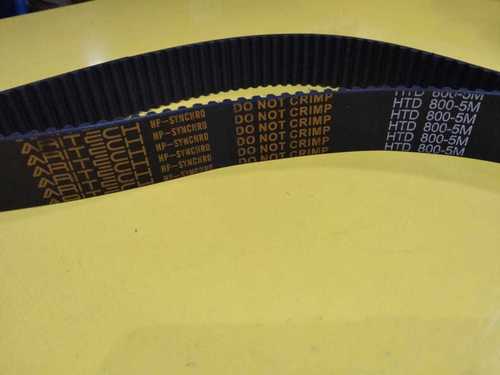

Timing Belt 5m

Material : Rubber with Reinforcement

Structure : Other, Flexible with Reinforcement

Type : HTD Timing Belt, Other

Resistant Feature : Other, Crimp Resistance

Usage & Applications : Power Transmission in Machinery

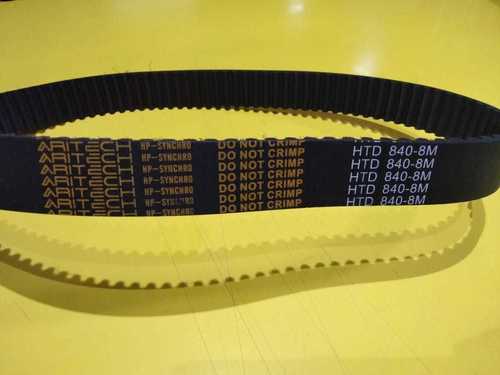

Timing Belt 8m

Material : Rubber with reinforced fiberglass

Structure : Other, Toothed belt structure

Type : Other, HTD 8408M

Resistant Feature : Other, Heat and wear resistance

Usage & Applications : Automotive industrial machinery and robotics

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS