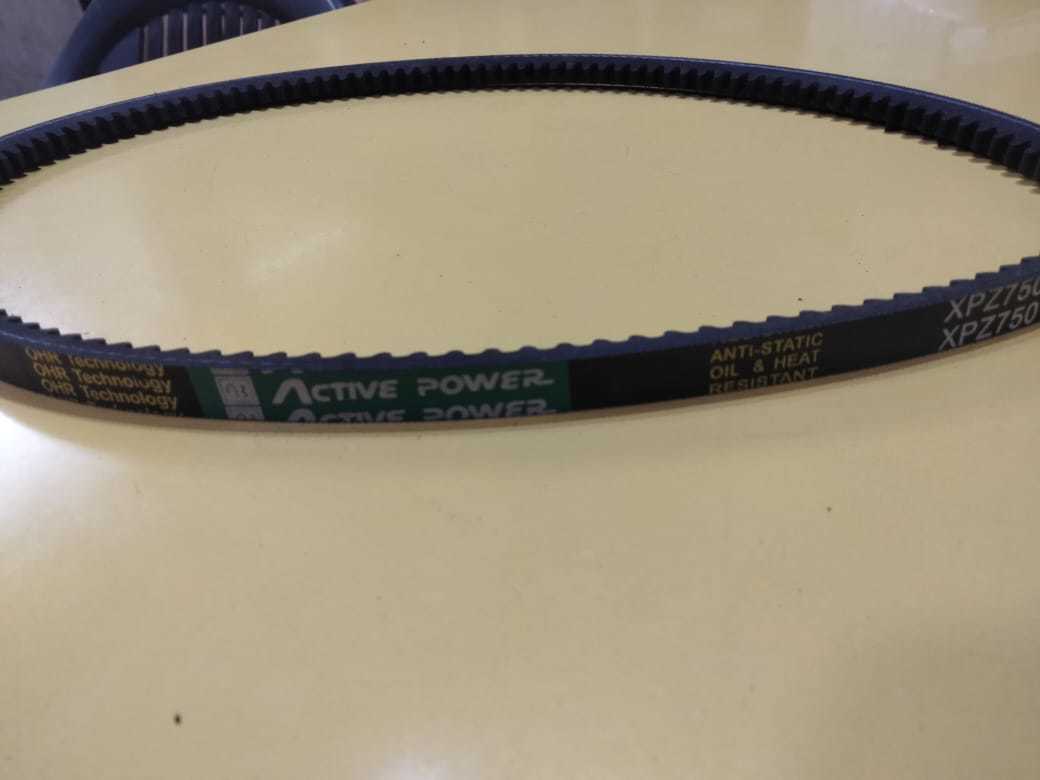

Cogged Wedge Belt XPZ

Cogged Wedge Belt XPZ Specification

- Belt Type

- Cogged Wedge Belt XPZ

- Material

- Rubber with synthetic cords

- Belt Color

- Black

- Belt Diameter

- Standard XPZ profile, approximate pitch diameter as per length

- Belt Edge

- Moulded cogged edges

- Hardness

- 75-80 Shore A

- Tolerance

- Length tolerance as per ISO 4184

- Width

- 10 mm (Nominal)

- Angle

- 40

About Cogged Wedge Belt XPZ

Feature

- Strong tensile members to give durability. Wedge profile allows for a smaller drive package and lower operating costs.

- Engineered cushion compound. Cut-edge cogged construction on most sizes.

- Better curves provide proper cord support and full contact with the pulley-groove for uniform loading, uniform wear, and increased belt life.

- High flexibility.

- 25% to 30% higher power ratings than wrapped V-belts.

Enhanced Power Transmission

With its cogged wedge design and reinforced synthetic cords, the XPZ belt ensures efficient transmission of higher loads over a wide range of speeds. Its advanced rubber material and precise profile minimize energy loss, making it ideal for robust industrial and automotive applications where power reliability is vital.

Designed for Versatility and Endurance

Engineered to operate in challenging environments, this belt resists heat and oil, performs from -30C to +80C, and maintains consistent tension. Suitable for single-band installations, the belts moulded cogged edges and 75-80 Shore A hardness ensure long service life, reducing maintenance needs in industrial, agricultural, and automotive equipment.

FAQs of Cogged Wedge Belt XPZ:

Q: How is the Cogged Wedge Belt XPZ commonly used in industrial and automotive machinery?

A: The Cogged Wedge Belt XPZ is typically used to transmit high power efficiently between rotating shafts in industrial machinery, automotive drive systems, and agricultural equipment, ensuring smooth and consistent operation.Q: What are the main benefits of choosing a Cogged Wedge Belt XPZ with synthetic cords?

A: Synthetic cords provide superior tensile strength, improved flexibility, and excellent resistance to elongation, resulting in consistent performance, longer lifespan, and reduced risk of slippage during operation.Q: When should this belt be replaced to ensure safe and optimal equipment performance?

A: It is advisable to inspect and replace the belt at signs of significant wear, cracks, or loss of tension, or during routine scheduled maintenance as specified by the equipment manufacturer. Regular checks help prevent unexpected failures and downtime.Q: Where can I source Cogged Wedge Belt XPZ in India?

A: This belt is available through authorized distributors and suppliers across India. Ensure you are purchasing from reputable sources for genuine quality meeting ISO 4184 tolerance standards.Q: What process ensures the accuracy of the belts dimensions and tolerances?

A: The manufacturing process involves precision moulding of edges, strict adherence to the standard XPZ profile, and compliance with ISO 4184 for length tolerances, ensuring the belt fits and performs as intended in compatible pulleys.Q: How does the belts temperature and oil resistance benefit its usage?

A: With a working range from -30C to +80C and resistance to oil, the belt maintains flexibility, strength, and performance even in harsh, high-temperature, or oily environments typically found in industrial and automotive settings.Q: What distinguishes the band type and belt type of this product?

A: The XPZ is a single band, cogged wedge belt designed for greater power transmission and stability. The cogged profile reduces slippage and enables better grip, making it suitable for various demanding applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cogged Belts Category

Cogged V- Belts

Minimum Order Quantity : 10 Pieces

Material : Rubber

Warranty : Yes

Structure : Belt

Cogged Wedge Belt XPC

Material : Other, Rubber, Polyester Cord

Belt Diameter : Custom/Standard (as per application)

Belt Edge : Cut Edge

Cogged Wedge Belt XBP

Material : Other, Rubber with Polyester Cord

Belt Diameter : Standard Depending On Model

Belt Edge : Cut Edge

Cogged Banded V-Belts

Minimum Order Quantity : 10 Pieces

Material : Rubber

Warranty : Yes

Structure : Belt

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free